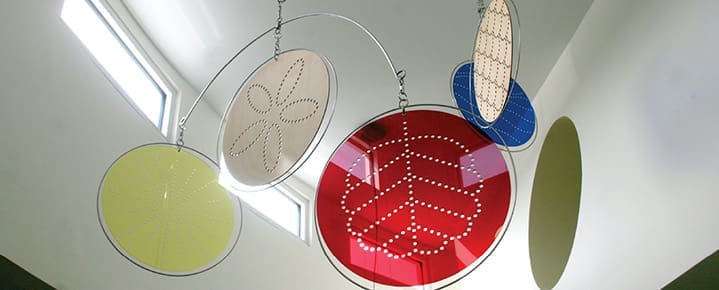

The Sterling Products team are experts in custom signage design and manufacture. We can guide you through the conceptual development, component design, material selection and best manufacturing process for the project.

Whether you need outdoor or indoor signage, 2D or 3D signs or unique products to enhance your architecture, Sterling has you covered.

Thermoforming/Vacuum-Forming

Advantages of Thermoforming/Vacuum-Forming

Vacuum forming technology can produce virtually any moulded shape with available modern moulding plastics like High Impact Polystyrene, Polycarbonate and ABS plastics. It’s perfect for outdoor, illuminated, or indoor signage and branding.

Thermoforming or vacuum forming is the process of heating a sheet of plastic and using a vacuum to stretch it over a precision-cut master mould. Excess material is trimmed with a CNC cutter.

Thermoforming is a preferred solution for medium to high volume production compared to the expensive tooling setup for injection moulding. Our largest thermo-former can work with sheets up to 3000mm x 1500mm. Textures can also be applied to the material to provide an almost infinite range of design possibilities.

Our specialists can provide free consultation on material selection and mould engineering which best suits your requirements

Why Vacuum-Forming?

Sterling Products has experience working with and moulding a large variety of plastic products. Known widely as vacuum forming, this process lends itself to the manufacture of products suitable for a variety of end use applications. When it comes to plastic products, vacuum-forming is also known as one of the most cost-effective solutions.

Thermo-forming has other advantages over other plastic forming processes allowing us to provide products quickly, often far faster than other alternative methods.

Economical Production Tooling

Tooling can be created using workable materials. Wood and glass-filled epoxy are typical examples of machinable materials typically used for vacuum-forming applications. With higher production runs, water-cooled aluminium tools are preferred for their longevity as they will process many thousands of formed units.

Turn-Around Times

One of the most significant factors when looking at plastic product manufacture, and the volume and repeat-ability of ongoing production, is the tooling or product mould itself. The methods and the ability to make these tools ourselves allows us to setup the tool and get the job happening much faster than other plastic moulding processes.

This is often a critical factor when looking at products being developed and made available with the minimum time taken overall. The process time when the moulding is in progress is fast by manufacturing standards allowing hundreds of units to be formed per day.

Large Part Capability

Sterling Products can produce a formed part up to 3000mm x 1500mm. Material pull or depth of draw, depends largely on the material selection and thickness. The tools and the type of plastics that suit a particular project are carefully chosen and deliberately made to work together to provide the required outcome.

Selection of Suitable Materials

Many materials respond very well to Thermo-forming including. ABS, HDPE, HIPS, PC, PVC, PP, PETG and Acrylic just to name a few. A variety of other plastic formulations can also be formed.

Blow-Moulding

Blow-Moulding

Blow moulding is the way toward framing a liquid cylinder (alluded to as the parison or preform) of thermoplastic material (polymer) and setting the parison or preform inside a mould cavity and swelling the cylinder with packed air, to take the state of the depression and cool the part before expelling from the mould.

Custom size spherical, oval and rectangular shaped domes

Clear, tinted or coloured acrylic

- Skylight

- Display Covers

- Signage

- Security Camera Covers

CNC/Laser Cut

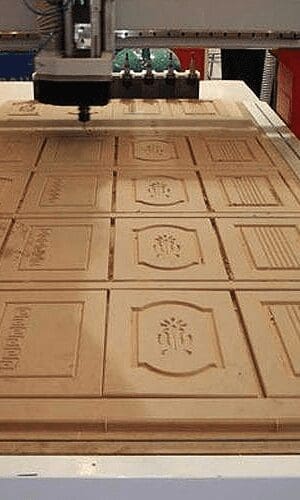

CNC

CNC trimming is extremely accurate with fine tolerances and is highly repeatable, fast, and precise. We can route up to 3000x1500mm x 100mm. With depths over 100mm, our designers and operators are able to split the job in parts before the final assembly.

Our CNC equipment is suitable for cutting all types of materials and uses a strong vacuum hold down system, often allowing several sheets to be cut at once. It is not uncommon for us to profile cut, engrave and mill a 3D shape all in the same day.

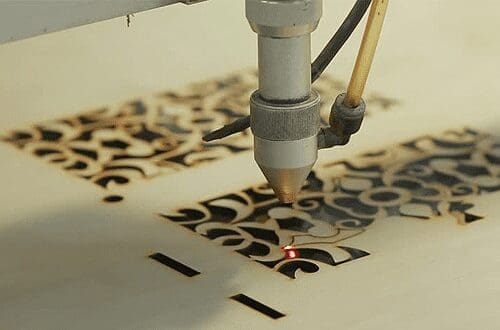

Laser Cut (Plastics)

We can laser up to 1300×900mm on our laser and even larger on our Industrial CNC machine, working up to 3000×1500mm.

Laser cutting technology allows us to cut intricate profiles without the necessity for tooling and at a comparable speed than other cutting techniques. It also offers reduced material contamination.

Prints & Graphics

UV Flatbed Printing/Digital Printing

Advancing technology and innovations allow us to transform colourful graphic design and printed image creations into stunning 3D products. We were the first company in Australia capable of reverse printing direct to sheet prior to vacuum forming to produce the finished 3D panel. Producing UV stable and vandal resistant moulded acrylic and plastic products was previously not possible.

Our in-house digital printing and graphics team uses the latest available technology to print directly to acrylic or plastic substrate before the molding process to form 3D shaped items. This is a new frontier with a range of exciting possibilities. Our team of experienced product designers ensure the highest quality and consistency.

Key Benefits to UV Printing Process

Multiple printed product applications – Plastics, Metals, Timber, Glass and Ceramic and more with unsurpassed adhesion.

Superior ink adhesion capable of supporting more than the weight of the reverse printed product.

Dual sided print panels option, in full colour high resolution quality on Acrylic, PETG, High Impact, ABS, Styrene etc.

Reflective for front-lit or Transmissive for Back-lit prints direct to surface without peeling over time which is common for vinyl applied application.

Fade-resistance of print images, filtered from Ultra Violet rays by the material selected before being printed. Increased longevity and colour vibrancy retention.

Scratch and Damage resistance provided by the correct material selection for reverse printed applications. The printed image is protected by the material itself.

Print panels up to 2000 mm wide and up to 50 mm thick to desired length – dependent on available stock sizes of chosen material.

Vinyl Graphics

Commonly used for vehicle wraps and window displays, vinyl cut graphics are an effective and affordable way to advertise. There are many different uses for vinyl decals and lettering, and typically the application of cut vinyl is as simple as peeling off the back off a sticker. It is generally used to decorate shopfronts, offices, cars, signage, glass windows and interior walls.

Gerber Edge FX

Gerber Technology

The Gerber Edge FX thermal printing system provides the ability to produce rugged cut to shape graphics, labels and decals to suit a variety of applications. The thermal transfer system incorporates a vast array of colour foils which allows for rich solid colours, the ability to print on reverse media further improves durability. Speciality foils including metallics can provide a visually appealing look that normal printers are unable to match. Paired with the Gerber enVision cutter, decals of any shape can be created.

For extremely durable and long lasting, stickers, labels and decals, Lexedge II is the perfect media and is available in stain and gloss finish. Once reverse printed and backed with a 3M self-adhesive, the cut to shape decals can be affixed to almost any surface. Perfect for use as operation labels for all kinds of equipment, on ATM’s and as general stickers. Lexedge II is thicker than a normal sticker the Lexedge II advantage is able to mask minor imperfections in surfaces while offering increased resistance to unwanted removal and damage.

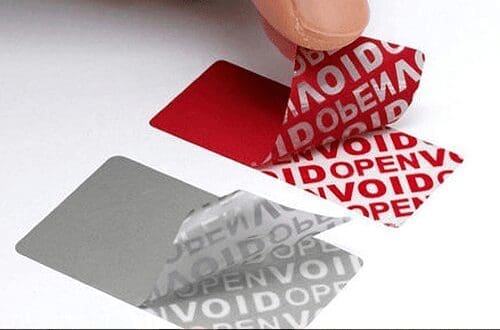

The Gerber Edge FX system can also print on regular clear adhesive films, which when combined with its white and contour cut capacities offers broader design options when producing window decals or other reverse applications. Specialist films such as the new tamper evident self-adhesive affords product security, providing the end user with the piece of mind components are still sealed. The words ‘VOID OPEN’ appear when the film has been removed within 90 days.

Highlights:

- Durable outdoor graphics resistant to the weather and damage

- Print and contour cut custom shape designs

- Perfect for signs, exhibits, labels and decals, window graphics, point-of purchase

- White, clear, metallic, reflective media options.

- All types of labels, from warning, ID, instructional, or even directional.

- Tamper evident labels

Industries:

- Signage

- Architectural

- Industrial

- Manufacturing

- Vehicle interior and exterior

- Government

- Military

- Packaging

Application Opportunities:

- General stickers and signage decals

- Safety and warning labels

- Control panels

- Gauge, dial and switch decals

- Barcode and Qcode labels

- Directional and instructional

- Window graphics and safety strips

- Tamper proof decals

- Low surface energy (adhesion) surfaces

- Compliance labels

General Plastics Fabrication

Fabrication Specialists

Our plastic fabrication specialists employ a wide range of techniques and equipment to produce eye-catching results – from heating and forming, line bending, welding and general fabrication.

Using a 3-Axis CNC cutter to profile the plastic, hot bar benders to create straight bends and fasteners and glues to bond components together. We also create sub-assemblies for our clients which reduce production times in their manufacturing plant.

Plastics Products Manufacture

Sterling Products offer a build-by-build project service, meaning special items can be built as required. With many years of experience, Sterling Product’s Team is well equipped to successfully undertake unique and bespoke or one-off projects.

Even in as saturated a market of possibilities as the point-of-sales specialty area is, we often asked to provide something different in the ever elusive pursuit of making a product visible or to stand out to the potential purchaser. Provision of those uniquely different solutions to the client is another of our fields of specialty.

With full in-house design and manufacturing capabilities, we can produce a design tailored to your specific requirements.

Industrial Design Services

New Product Innovation

Innovation matters. In the consumer product realm, it can drive profitability and growth, and it can help companies succeed—even during tough economic times. On the opposite side of the sales counter, consumers have a strong appetite for innovation, but they’re increasingly demanding and expect more choice than ever before.

The advances in technology, materials and resources at Sterling Products provides limitless possibilities. We have qualified and highly skilled professionals in all aspects of display and sign manufacture. You can be confident of Sterling’s ability to deliver you message with professionalism, style, and in accordance with the required specifications.

Design Specialist

When you require assistance to progress your ideas further, Sterling Products has the design capabilities, CAD software systems and technology to assist customers with complete component design, refinement and manufacturing. Our experienced team can guide you through the conceptual development of component design, material selection and the manufacturing process. We continually assess progress throughout the project to ensure cost effective processes are utilised.

We are equally at home working with your designers and architects to achieve the desired product outcome.

No Comments

Sorry, the comment form is closed at this time.